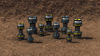

Geopress K and Geopress K gas

Press connection technology that is robust and reliable.

- For drinking water

- d25 to d63

- Including an EPDM sealing element compliant with the products for use in contact with drinking water, AS/NZS 4020

- Blue clamping ring

- Marked with a green Smart Connect feature dot

Geopress K gas

- For natural gas and liquid gas pursuant to AS/NZS 4129 and for hydrogen supply

- d32 to d63

- Featuring an HNBR sealing element

- Yellow clamping ring

- Marked with a yellow Smart Connect feature dot

The two Geopress K systems of Viega, Geopress K and Geopress K gas, offer internal sealing system solutions for supplying drinking water, gas and the energy source of future – hydrogen. The press connecting systems made of high-strength fibreglass reinforced polymer were developed specially for use in ground soil. They combine the advantages of Viega's cost- and time-saving press connection technology with the highest material quality and safety of the Smart Connect feature. A perfect combination making Viega the perfect choice for all types of supply technology.

When it comes to underground pipelines, many factors must be considered. They need to be made of a corrosion-resistant and durable material that can withstand the high strains it will be exposed to. Cost-effectiveness is also important – not just the price of a connector but also the time it takes to install, no matter what the weather conditions.

The solution – by Viega

Geopress K and Geopress K gas satisfies each and every challenge posed by underground installations. The system offers the reliability of press connection technology with internal sealing that’s robust and extremely economical.

The system – versatile

The two Geopress K systems offer the highest possible safety in connection with a great variety of HDPE pipe types. HDPE-80, HDPE-100 and HDPE-100 HSCR – any pipe of the SDR class 11 – can be easily combined with Viega Geopress K and Geopress K gas.

Visibly pressed

The clamping ring of the Geopress K and Geopress K gas connectors fulfills two functions: On the one hand, it ensures a connection that is high-tensile and, on the other hand, it serves as an unmistakable marker that the connection is correctly pressed. This is because the clamping ring only becomes visible on the outside of the pipe after the pipe has been pressed, thus indicating a complete and safe pressing.

Tensile stress resistant

The approval granted to the Geopress K systems confirms that the connection will remain tight and firm even under extreme tensile stress. The clamping ring permanently connects the pipe and connector – so that even digger shovels cannot destroy it

Optimal hydraulic design

Thanks to its optimised internal geometry, the Geopress K and Geopress K gas connectors, elbows and T-pieces provide optimal flow characteristics.

| Reasons to Choose Geopress K and Geopress K gas |

|

|

|

|

|

|

|

|

Tapping Valves. A safe service connection right from the start.

Market leading technology can be identified easily if it makes your work easier – just like the tapping valves of Viega. With 43 various outlets for three systems, they provide the highest flexibility for the job and are the ideal connection to Geopress K. The fittings are also made from high-strength polymer and are available for drinking water (9690TW) and gas (9690G). The material ensures enormous stability and superior durability – features that are of utmost importance for underground installations.

With the tapping valve, the spot drilling of the main supply line takes only a few minutes. It is placed around the pipe like a bracket and tightly connected with the pipe using the press tool. Due to the integrated miller for PE pipes, the drilling can be carried out directly without having to use an external drilling machine. To ensure the anti-twist protection of the tapping valve, a sleeve will be inserted into the drill hole.

Advantages of press connection technology at a glance

Time savings

Pressing piping significantly reduces installation time compared to welding. This is because there is no need to spend time preparing the pipe surface or wait for welded joints to cool.

Reliability

Geopress K systems are equipped with the tried-and-tested Viega SC-Contur, which ensures a tight seal and makes inadvertently unpressed connections immediately visible when the service connection is tested for leaks.

Cost efficiency

Viega’s innovative press connection technology also significantly minimises costs. It is not just the overall assembly time on construction sites that is significantly reduced. The use of press connection technology also eliminates qualification costs for PE welders.

Flexibility

Compared to welding technology, Viega press connection technology delivers incredible flexibility on construction sites. Firstly, because you can work regardless of the weather. Secondly, because no special training is required to make the press connections. Another advantage is that with press connection technology, you do not need a power supply on site.